Lesson 7: HEAT TREATMENT III – heat treatment of steels

In this lesson, we’ll delve into the various heat treatment processes applied to steels, unlocking their full potential and enhancing their mechanical properties.

- Annealings

- Annealing processes aim to improve the machinability and structural properties of steels.

1.1. Stress Relieving

- Stress relieving eliminates internal residual stresses caused by factors like cold working, phase changes, or temperature gradients.

- Effective above 400°C but limited to Ac1 to preserve material structure and properties.

- Slow cooling post-treatment prevents additional residual stress formation.

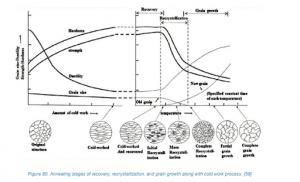

1.2. Recrystallization Annealing

- Applicable to various metals and alloys.

- Restores deformed grain structures to equilibrium states.

- Recrystallization temperature varies with the degree of prior deformation.

- Can result in either complete or partial recrystallization, influencing grain size.

1.3. Coarse-Grain Annealing

- Improves machinability in highly ductile materials, like low-carbon mild steels.

- Annealing at temperatures above Ac3 encourages grain coarsening.

- Cooling rates, temperature, and time control grain size and growth.

1.4. Spheroidizing

- Enhances the machinability and ductility of ferrite-pearlite and ferrite-cementite steels.

- Transforms cementite into spherical shapes within the steel matrix, improving material properties.

- Reduces tool wear during machining.

1.5. Normalizing

- Achieves a uniformly distributed ferrite-pearlite or pearlite-carbide microstructure.

- Based on equilibrium α-γ-α transformation, cooling in still air.

- Used in low-alloyed steels and as an intermediate step before hardening.

1.6. Supercritical or Full Annealing

- Improves machinability and grain structure in non-uniform or coarse-grained materials.

- Involves converting material to austenite, followed by controlled slow cooling.

- Cooling rate determined by desired hardness, with final cooling in an oven or still air.

1.7. Isothermal Annealing

- Reduces annealing time, minimizes residual stress, and ensures uniform hardness.

- Improves machinability and reduces distortion in low carbon mild steel.

- Results in a fabric structure of ferrite and fine pearlite.

1.8. Annealing of Austenitic Steels

- Applied to austenitic Cr-Ni and Mn steels to achieve a homogeneous austenitic microstructure.

- Eliminates intergranular corrosion susceptibility by eliminating chromium carbide precipitation.

- Carried out above the dissolution temperature and rapidly cooled in water.

- Hardening Heat Treatments

- High hardness is achieved through martensite and interstitial metallic compounds.

2.1. Quenching of Steel

- Martensite forms during rapid cooling from austenite.

- Transformation starts at Ms and ends at Mf, altering the crystal lattice and carbon content.

- High carbon content leads to greater martensite hardness.

2.2. Surface Hardening

- Impacts surface layers while leaving inner parts unchanged.

- Involves rapid heating of surface to austenitizing temperature and quick quenching.

- Processes like carburizing and nitriding introduce alloying elements for improved hardness.

2.3. Martempering

- Aims for martensitic microstructure with minimal thermal stress to prevent distortion and cracking.

- Involves cooling in metal or salt bath followed by air cooling.

- Toughening Heat Treatments

- Enhances material toughness, crucial for resistance to dynamic stresses.

3.1. Quenching and Tempering

- Forms spheroidite when martensite is tempered at high temperatures.

- Used to improve properties of steel with low carbon content.

3.2. Austempering

- Produces a pure bainitic microstructure through isothermal annealing.

- Mainly used for oil-quenched steels.

3.3. Patenting

- Applied to medium or high-carbon steel before wire drawing.

- Heating followed by cooling in molten lead or salt bath.

- Aims to increase formability and create a homogeneous fine pearlite structure.

Conclusion

- Steels offer a wide range of mechanical properties based on their microstructure.

- Understanding the diverse heat treatment processes empowers engineers to tailor steel properties to specific applications.

- Annealing, hardening, and toughening treatments play pivotal roles in achieving desired steel characteristics, enhancing their performance in various industries.

This lesson has unraveled the intricacies of heat treatment processes for steels, from annealing for improved machinability to hardening and toughening treatments that transform their mechanical properties. Armed with this knowledge, you can optimize steel performance for diverse applications, making it an indispensable skill in the world of materials engineering.