Lesson 7 – Maintenance strategies

In this lesson, we will explore various maintenance strategies and systems, which are essential for ensuring the efficient operation and longevity of machinery and equipment.

Understanding Maintenance Strategies

- Machine maintenance, also known as product aftercare or servicing, comes in various forms aimed at preserving the operational condition of products.

- Choosing the right maintenance strategy involves considering market demand, market penetration, operator needs, equipment requirements, design principles, spare parts availability, and environmental factors.

Implementing Maintenance Strategies

- Maintenance strategies can be categorized as long-term, strategic, or short-term, tactical.

- Long-term strategies include various maintenance regimes such as corrective, corrective replacement, planned preventive, preventive maintenance, and total maintenance.

- Short-term strategies encompass immediate solutions for unexpected issues.

Maintenance Systems

- Different maintenance systems have evolved to address the diverse nature of machinery failures and repairability.

- Various maintenance systems are selected based on economic considerations, including:

- On-demand maintenance and repair (“fire-fighting”).

- Planned preventive maintenance (PPM), either time-based or performance-based.

- Maintenance based on technical condition testing (diagnostics).

- Total Productive Maintenance (TPM).

- Reliability-Centered Maintenance (RCM).

Maintenance and Repair on an As-Needed Basis or as Replacement for a Defect

- In this system, repairs occur only after a failure has happened.

- Failed components or main parts are repaired or replaced when needed.

- Regular care and lubrication are essential.

- Advantages include maximum utilization of parts, but disadvantages include unplanned downtime and the need for a significant spare parts inventory.

Planned Preventive Maintenance (PPM)

- PPM is a widely used maintenance system focused on preventing faults and unforeseen breakdowns.

- Regular inspections and repairs are carried out according to a predefined maintenance schedule.

- This system is prevalent in various industries, promoting operational reliability through planned inspections and repairs.

Preventive Maintenance Based on Technical Condition Testing (Diagnostics)

- PMM relies on component wear analysis and logic.

- However, it may not provide a precise answer due to factors like quality variations, operating conditions, and uncertainties.

- To maintain equipment in a fit state for use, periodic or continuous technical condition tests are employed during operation.

Total Productive Maintenance (TPM)

- TPM, rooted in Japanese industry, engages all employees in preventive maintenance through small group activities.

- Operators take responsibility for routine machine maintenance.

- TPM includes steps such as improving equipment utilization, autonomous maintenance, planned maintenance, training programs, and designing reliable machinery.

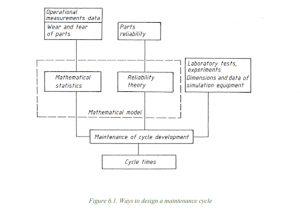

Establishing a Maintenance Cycle

- Machinery gradually loses usefulness during its service life until failure.

- Failures are influenced by operating conditions, time of use, and performance.

- To reduce breakdowns and downtime, a well-organized prevention strategy is necessary.

- A cycle schedule determines the intervals for inspections and repairs.

- Cycle schedules consider maintenance frequency, inspection and repair sequence, work types, and parameters (time, distance, etc.).

- Various methods, including wear analysis and economic calculations, are used to determine cycle times.

- Interventions are planned to prevent expected failures, based on operational, maintenance, and repair experience.

- Machine failure modes are often stochastic due to technical variations, material inconsistencies, manufacturing inaccuracies, and stress variations.

Conclusion

- Maintenance strategies are essential for preserving the operational condition of machinery and equipment.

- The choice of maintenance strategy depends on multiple factors, including market demand and equipment characteristics.

- Long-term and short-term maintenance systems cater to different needs.

- Preventive maintenance, based on both schedule and diagnostics, helps prevent unplanned breakdowns.

- Total Productive Maintenance involves all employees in machinery care.

- Establishing a maintenance cycle is crucial for maintaining equipment reliability and minimizing downtime.