Lesson 6 – Fault analysis and fault rectification

In this lesson, we will delve into the concepts of machinery failures, their analysis, and the steps involved in rectifying faults effectively.

Understanding Failures

- A failure is a state in which a machine cannot perform its intended function or has lost its wear reserve (WR) needed for functioning.

- Failures can disrupt production systems and result in significant losses, making it crucial to analyze their processes, causes, and consequences.

- Methods exist for detecting potential failures that haven’t occurred yet and for analyzing failures that have already happened.

Types of Failure Analysis

- IEC 50 (191):1992 introduces methods for both prospective failure analysis (predicting potential failures) and retrospective failure analysis (analyzing past failures).

- Additionally, weak-point analysis is a method closely related to these concepts.

- The term “damage analysis” is also used interchangeably with failure analysis, as failures often lead to damage, impacting machinery operability.

Diversity of Damage States

- Between nominal or new pseudo-potential and complete failure, there exists an infinite range of damage states.

- Damage effects are diverse, usually stochastic (random), and interconnected. Understanding these is crucial for design, manufacture, use, and maintenance.

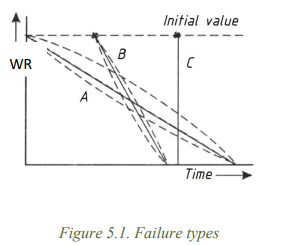

- Three main types of failures are gradual (soft failure), delayed (B-sign), and sudden (hard failure), each with distinct characteristics in terms of duration and impact.

Failure vs. Malfunction

- ISO IEC 50(191):1992 defines a failure as a condition where a product can’t perform its intended function, except during preventive maintenance or planned activities.

- Failures are a part of a process, often triggered by wear and tear caused by various stresses during the operational state.

- Technical failures occur during the process, affecting components but not necessarily causing a malfunction.

- Failure indicates a change in component quality due to identifiable causes, interpreted as an oc¬osity.

- A technical defect can occur during manufacturing or repair, which is different from a failure.

- Reliability is linked to failure, with higher reliability indicating a lower probability of failure.

- Failure is a process resulting from the deterioration of components during operation, reducing their technical reliability.

Reliability and Unreliability

- Technical unreliability is defined as a component or sub-assembly’s failure to perform its functions correctly under specific operating conditions for a defined time.

- This condition doesn’t always lead to failure, as sometimes unreliable components can still operate acceptably under certain conditions.

- Practical understanding of these concepts helps in identifying issues and improving machinery performance.

Failure types according to the duration and extent of the failure (figure 5.1)

- gradual failure (e.g. due to a condensation phenomenon)

- delayed failure

- sudden failure (e.g. a pneumatic hose fitting puncture)

Conclusion

- Failures are conditions where machinery can’t perform its intended function or loses its wear reserve.

- Analyzing failures, both prospective and retrospective, is crucial to minimize disruptions and losses in production systems.

- Damage states can vary widely, impacting machinery operability, and are essential to consider in maintenance.

- Recognizing the differences between failure, malfunction, and technical defect is vital for effective problem-solving in machinery maintenance.

Read the textbook from the 40th page. You can find the textbooks’s content on this link.