Lesson 3: Testing considerations in Electric Powertrain Laboratories

Introduction: When developing and testing electric machines, a controlled environment is vital. However, testing labs, like an automotive electric powertrain laboratory, can pose various hazards. This lesson will provide an understanding of the key considerations to ensure safety during testing.

Types of Hazards:

- Safety: Pertains to the risks related to high voltage operations and equipment.

- Physical: Concerns related to machinery, their operations, and mechanical setups.

- Chemical: Refers to the hazards associated with coolants and lubricants used in electric drives.

Safety Hazards:

- High Voltage Concerns:

- Labs typically operate at voltages reaching up to 1500 V.

- High voltage certified personnel are mandatory for electrical tasks.

- Special care must be taken with capacitors. Without safety discharge circuits, capacitors can remain charged and pose a danger.

- Electro-Magnetic Fields:

- Test beds and the UUT draw high currents, creating strong electromagnetic fields.

- Though cables are often shielded to reduce noise, shielding can’t fully block the magnetic fields.

- The resulting ElectroMagnetic Interference (EMI) may not only disturb devices but can also interfere with medical implants, such as pacemakers.

- High Rotation Speed:

- Modern electric drives can achieve rotation speeds of up to 20,000 rpm or even higher.

- This necessitates careful mechanical build considerations for the test setup.

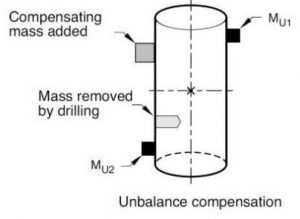

- Safety precautions include dynamic balancing of rotating parts and ensuring that all rotating components are covered by protective shielding.

Chemical Hazards:

- Cooling Systems:

- Liquid cooling systems are essential for taking away heat from electric drives.

- Two main types of coolants are used:

- Water or Water-Glycol Cooling: These often have distinctive colors and are designed to remain liquid across a wide temperature range.

- Oil Cooling: Usually involves Automatic Transmission Fluid (ATF) oils.

- It’s essential to monitor the temperature and avoid reaching the boiling points of these coolants to prevent the release of harmful fumes or vapour.

Figure Balancing

Physical Hazards:

- Due to high operational speeds, mechanical parts can get exceedingly hot. It’s crucial to avoid touching surfaces without proper precautions.

Conclusion: While electric powertrain laboratories are pivotal in the development and testing of electric vehicles, ensuring safety is paramount. Understanding the types of hazards and implementing the necessary precautions can make the testing environment safer for everyone involved.

Quiz:

- What type of hazard is associated with high-voltage operations?

- Why is dynamic balancing important for rotating parts in the test setup?

- Name the two main types of coolants used in electric drives.