Lesson 7 Environmental impact of business activities

Environmental impact of business activities

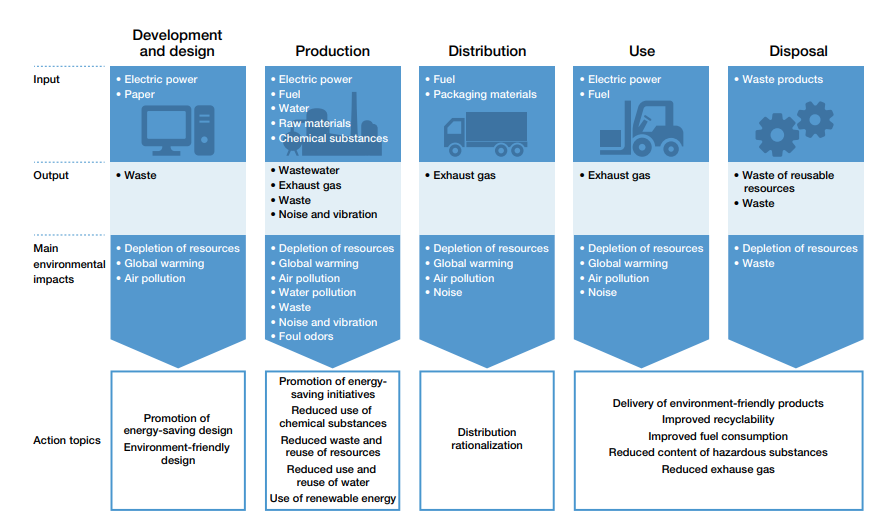

Toyota have been striving to grasp the overall picture of the use of natural resources and energy, and the consequential environmental impact over the entire life cycle of the product from the planning, development and design of a new product to its disposal, with the aim of promoting efficient activities and reducing environmental impact.

The input includes sources of energy such as power, water, paper used in offices, raw materials used for manufacturing the product, various kinds of chemical substances used in the production process, and fuel for transport vehicles used in the distribution stage. The effect of their consumption is the depletion of natural resources.

The output includes wastewater, exhaust gas and other wastes generated in the manufacturing stages, and carbon dioxide produced by the consumption of fuel and energy, which have various environmental impacts.

To reduce these environmental impacts, Toyota have been establishing daily controls, setting goals and promoting environmental activities.

3‑6. Figure_Environmental impact of business activities – TOYOTA

[Environmental Management | Toyota Industries Corporation (toyota-industries.com)]

Life Cycle Assessment

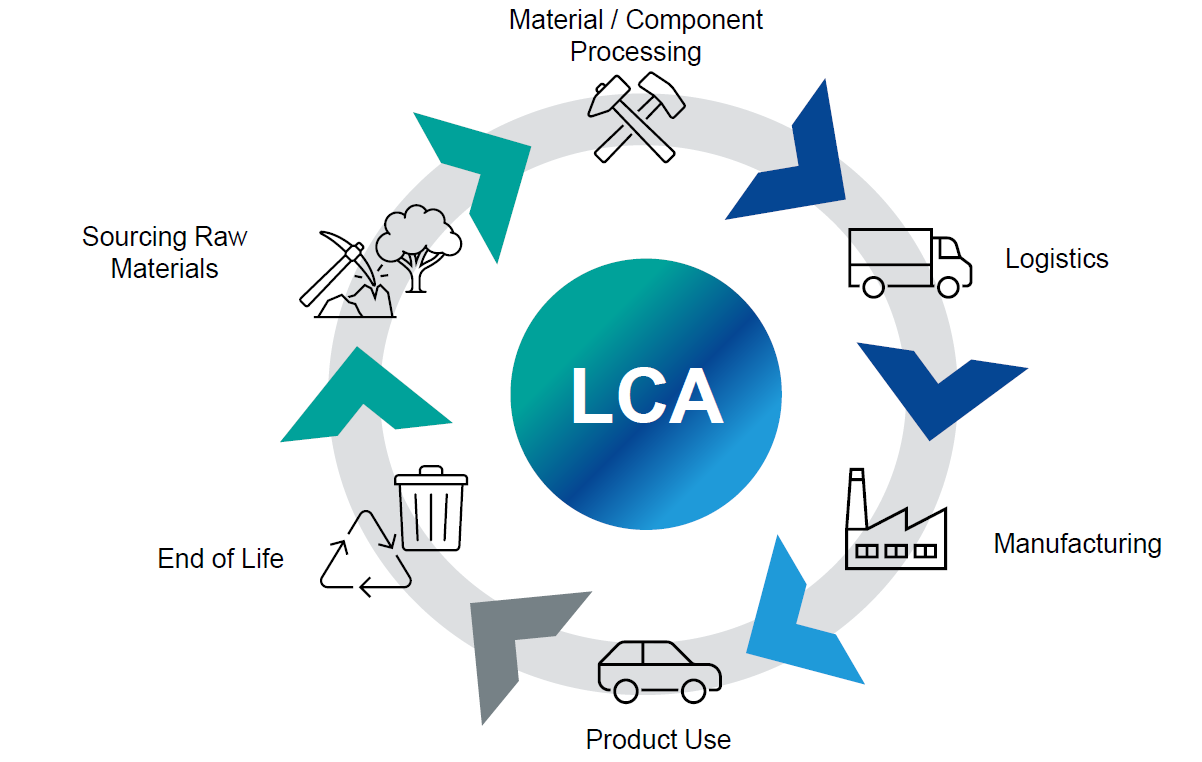

LCA (Life Cycle Assessment) is a method of assessing the environmental impact of a product or service throughout its life cycle (resource extraction – raw material production – product production – distribution and consumption – disposal and recycling).

LCA is a method for evaluating the environmental impact of products and services throughout their life cycle (resource extraction – raw material production – product production – distribution and consumption – disposal and recycling). LCA is specified in the international standards ISO 14040 and 14044.

3‑7. Figure_Life Cycle Assessment

[https://www.horiba.com/esp/applications/energy-and-environment/energy-usage-optimization/lca/]

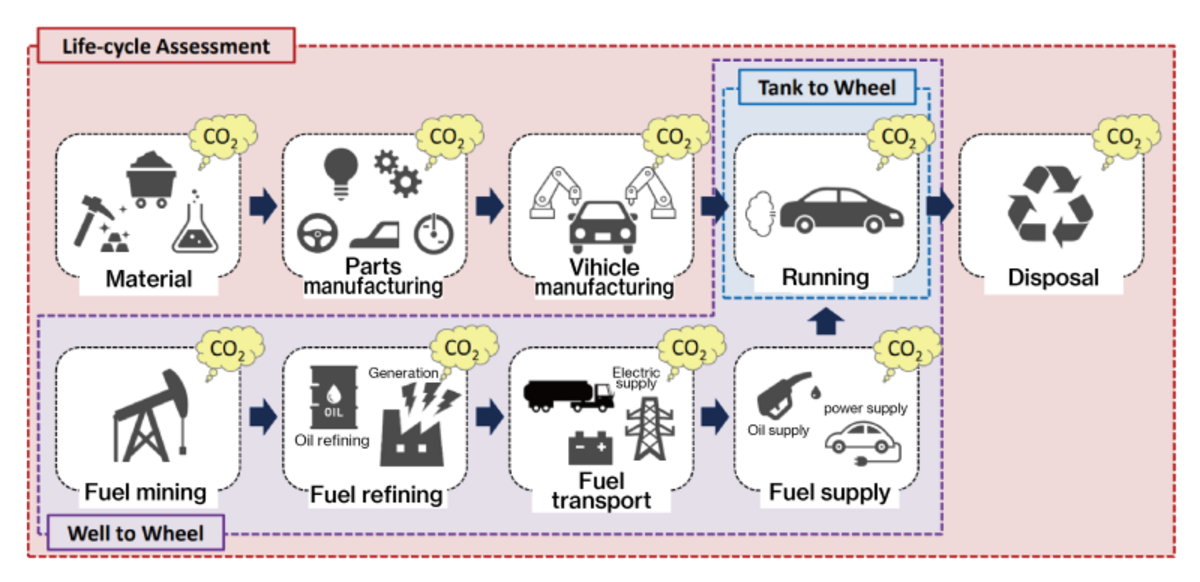

The 3‑8. Figure is an overview of LCA for automobiles. Conventionally, the focus was only on CO2 emissions during driving. Nowadays, however, as required by LCA, it is the manufacturer’s responsibility to reduce environmental impacts at all phases of the product life cycle, from fuel mining and materials procurement to manufacturing, use, disposal, and recycling.

3‑8. Figure_ LCA for automobiles

[https://www.horiba.com/esp/applications/energy-and-environment/energy-usage-optimization/lca/]

A full life cycle assessment (LCA) of a vehicle’s emissions is an essential step towards sustainable use of the world’s resources. An LCA covers production of the raw materials, use of the product, and its end of life including recycling and reuse. It enables manufacturers and material suppliers to accurately evaluate the potential environmental impact of their products or materials over their life cycle.

Current regulations in the automotive sector only focus on the use phase of a vehicle’s life. This pushes carmakers to reduce weight but ignores the production and end-of-life phases of a car’s lifecycle.

While the use phase of an internal combustion vehicle’s life cycle currently produces the most greenhouse gas emissions, this is not the case for emerging powertrains. Vehicles powered by solar-generated electricity or bio-fuels have very low levels of emissions during their useful life, making the production and end-of-life phases more important.

To address these concerns, the introduction of LCA emissions legislation which covers the vehicle’s entire life is necessary.

Current regulations in most parts of the world only consider the use phase of the vehicle’s life.

Adopting a life cycle assessment (LCA) approach to regulation ensures that emissions across all phases of a vehicle’s life cycle, and the supply chain, are considered.

While existing legislation has driven down tailpipe emissions during the use phase, it has also shifted the environmental burden to the production and recycling phases of the vehicle’s life. The unintended consequence is that overall transportation emissions might increase, even as tailpipe emissions are lowered. Emissions from the manufacture and disposal phases of a vehicle’s life are an increasingly significant part of its life cycle emissions. This is particularly noticeable in vehicles made from synthetic materials.

Adopting an LCA approach would encourage emission savings across life cycle phases and the supply chain. Ultimately it would ensure that overall emissions from transportation are lowered. The LCA approach would also give carmakers a wider range of material options and benefit their competitiveness.

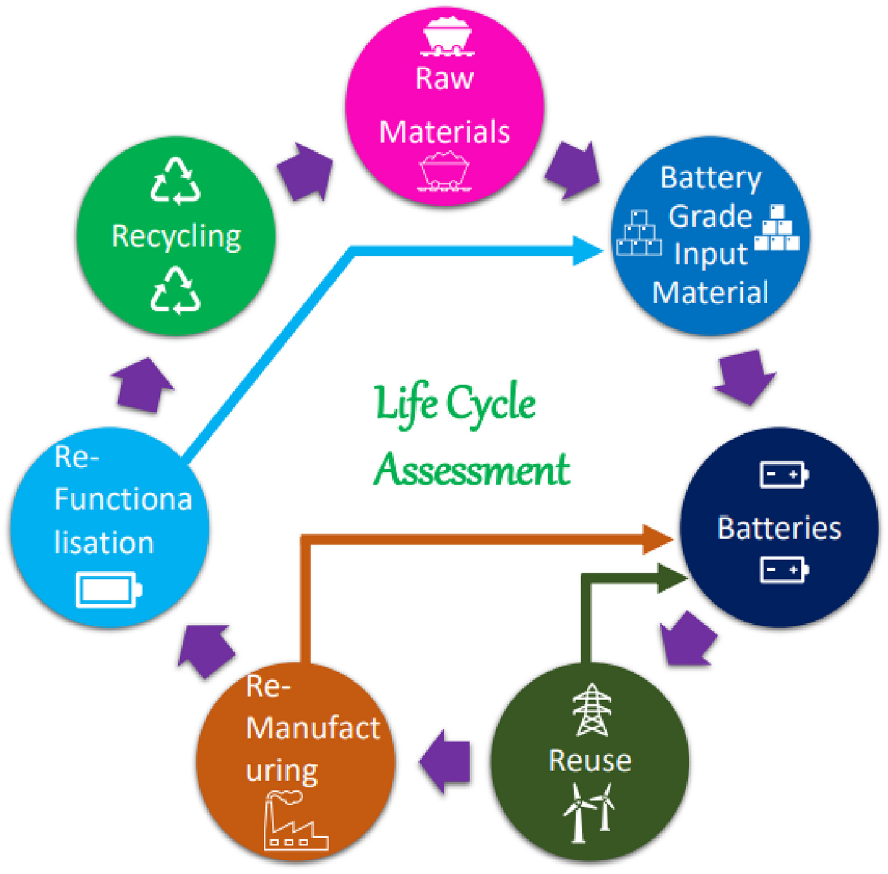

3‑10. Figure_ LCA of Li-ion battery from its “cradle” to “grave”

[https://doi.org/10.1002/wene.481]

Through the LCA analysis, it is possible to know the environmental feasibility of LIB recycling, whether the recycling increases the environmental burdens or decreases the environmental impacts.