Lesson 6: Recovery of glass waste from the automotive industry

RECOVERY OF GLASS WASTE FROM THE AUTOMOTIVE INDUSTRY

The flat glass used in windscreens, side windows, backlights, panoramic sunroofs, and mirrors is an essential part of a vehicle. It is designed so that if it breaks, no dangerous sharp shards will result. It is meant to guarantee unaltered visibility to drivers and safety to vehicle occupants in case of an accident. It is also an essential part of a vehicle design and a substrate for the integration of sensors, cameras and lidar, enabling assisted and automated driving. Auto glass is also designed to withstand the force of wind from high-speed driving, the impact of road debris, and also support the structure of the cabin during collisions.

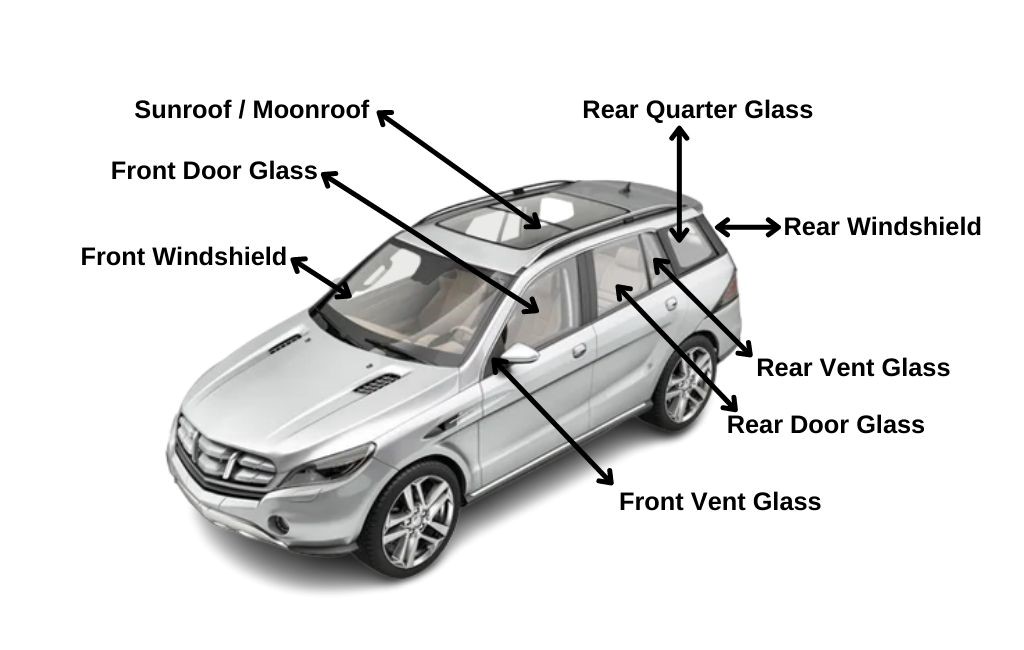

The common auto glass parts are shown in 4‑1. Figure.

4‑1. Figure_ Auto glass parts

[https://www.glassfixitauto.com/blog/auto-glass-parts/]

The automotive glass have specific options and are made with different glass techniques such as windscreens with rain sensor, tinted glass or athermic glass; tempered front door sidelights; laminated front door sidelights; tempered rear door sidelights; laminated rear door sidelights; and fixed backlights [[i]].

When windshields are recycled PVB must be separated from the glass. In most cases, the used windshields are first pulverized or crushed. After that, a machine separates the glass from the PVB. The glass is processed into something called “glass cullet,” which can be used in a variety of applications, such as concrete, fiberglass insulation, asphalt and more. The PVB also can be used for various adhesive applications [[ii]].

Because this process is so difficult, many auto glass companies have entered into agreements with laminated recyclers to recycle windshields and subcontract their recycling after replacing the windshields.

The same features that make windshields tough and safe also make them difficult to recycle. By design, the glass is tightly bonded to the rubbery sheet of PVB and adheres strongly even after the glass breaks.

So even though glass recyclers process many millions of metric tons of container glass annually, they have traditionally recycled very few windshields.

Utilizing the high-quality characteristics of automotive glass, powdered glass from shredder residue is recycled into tiles with remarkable density and strength, and also used as materials for landscaping pavement.

The European flat glass industry is eager to collect and use more flat glass waste, aka ‘cullet’, in its manufacturing process to decrease the use of virgin raw materials and reduce CO2 emissions. End-of-life automotive glass pieces could be a new source of cullet if collection, sorting and quality can be improved.

EXAMPLE: Waste Windshield-Derived Silicon/Carbon Nanocomposites as High-Performance Lithium-Ion Battery Anodes

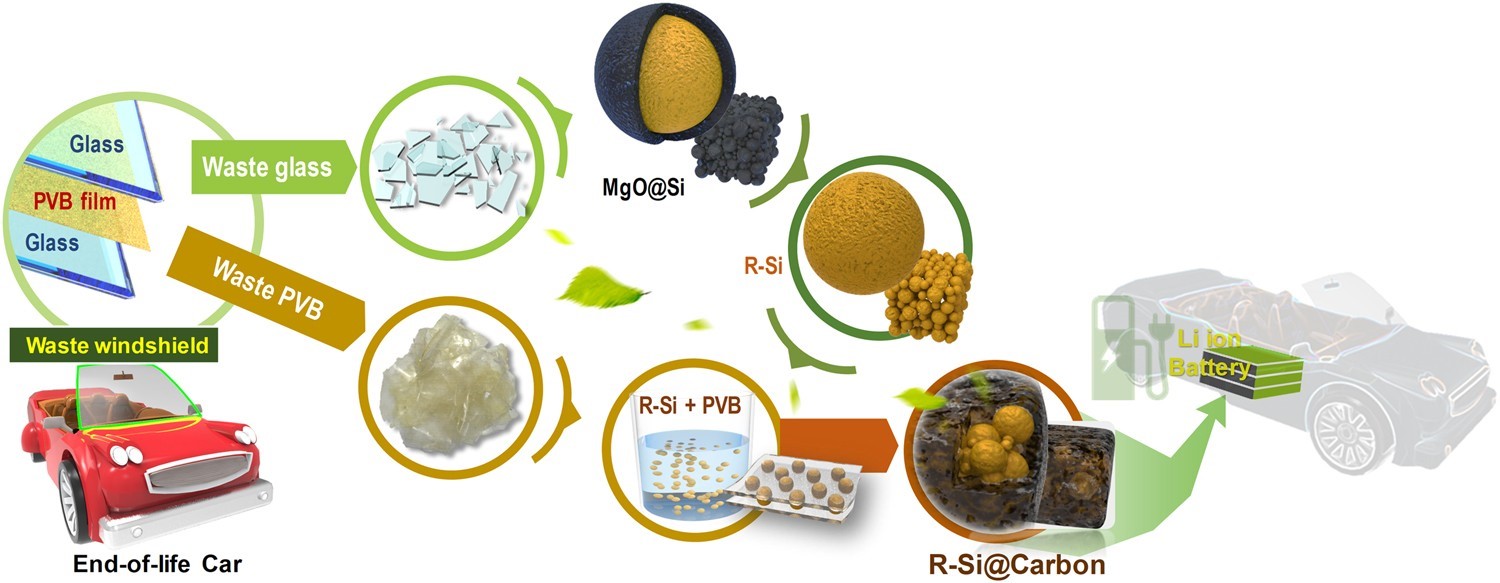

Waste glass is mainly composed of amorphous silica (64%), which is a suitable silicon source. Waste glass is typically collected from various industrial wastes, such as windows, displays, bottles, and glass products. The collected waste glass is recycled for use as raw materials or manufactured goods. Laminated glass from windshield end in landfill because of polyvinyl butyral (PVB) adhesive films between two glasses. The waste PVB film leads to a laborious recycling process to separate the glass and PVB film. However, the organic PVB film can be an appropriate carbon source due to its 67.6% carbon content. In laminated glass derived from waste windshields, the glass and PVB film can be the silicon and the carbon precursors, respectively. This work represents the first synthesis of a silicon/carbon composite anode for LIBs using waste windshields as both silicon and carbon precursors.

3D silicon anodes was synthesized using glass from waste windshields via magnesiothermic reduction and acid-treatment. To further improve the electrochemical properties, silicon/carbon composites are fabricated using PVB films from windshields via a simple carbonization process. The silicon/carbon composite electrodes demonstrated high capacity and long cycle life due to their unique nanostructures and inclusion of conductive carbon. During the synthesis processes, reduced Si (R-Si) and R-Si/carbon composites are obtained; these samples are named R-Si@PVBn (n = 40 or 100) depending on the PVB/R-Si weight ratio.

4‑4. Figure_Schematic of the synthesis method of reduced silicon and silicon/carbon composites for lithium-ion batteries

[https://doi.org/10.1038/s41598-018-19529-1]

To obtain better cycling retention, R-Si/carbon composites were fabricated using waste PVB film as the carbon resource. The R-Si@PVB40 and R-Si@PVB100 electrodes exhibited excellent cycling retention, compared with the R-Si electrodes. This cost-effective fabrication method, which produces a high-performance silicon/carbon composite anode material, is advantageous for its various potential use in recycling industry of waste windshields [[i]].

[[i]] Choi, M., Kim, JC. & Kim, DW. Waste Windshield-Derived Silicon/Carbon Nanocomposites as High-Performance Lithium-Ion Battery Anodes. Scientific Reports 8, 960 (2018). https://doi.org/10.1038/s41598-018-19529-1

[[i]]https://www.windshieldexperts.com/blog/different-types-of-car-glass-windows-that-everyone-should-know/