Lesson 5: Methods that meet today’s requirements – repair welding of iron casting, and reconditioning of aluminium castings

In this lesson, we will explore two important methods for repair and reconditioning of castings – Repair Welding of Iron Castings and Reconditioning of Aluminium Castings.

- REPAIR WELDING OF IRON CASTINGS

Introduction

- Iron castings come in various sizes and shapes, making replacement challenging for specially designed and large castings.

- Repair welding offers a solution for professional repair, but it involves specific methods.

Welding Methods for Cast Iron

- Three primary methods for repairing cast iron are Cold Welding (no preheating), Semi-Hot Welding (preheating to 300-400°C), and Hot Welding (preheating to 500-600°C).

- Cold welding is preferred for custom repair welding due to its simplicity and effectiveness.

Operations

- Part preparation involves cleaning, defect type inspection, extent assessment, and disassembly planning.

- Preparing the surface by rounding edges, corners, and marking the crack trace.

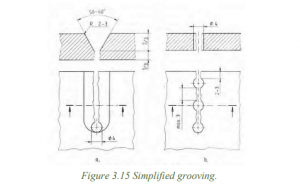

- Grooving the electrode and engraving.

- Grinding to remove stone residue.

Performing a Repair Weld

- Using a thin 2-2.5 mm diameter nickel-based electrode with 40-60 A current to minimize heat input.

- Applying the weld sections sequentially to avoid concentrated heat.

- Preventing crack propagation with two auxiliary welds perpendicular to the weld section.

- Hammering to reduce the brittle cementitious fabric structure and weld zone stresses.

- Continuous removal of slag residues.

- Quality control methods depend on the part’s function, including paint penetration tests, ultrasonic testing, or radioisotope testing for high-value or high-risk equipment.

- RECONDITIONING OF ALUMINIUM CASTINGS

Introduction

- Aluminium castings are widely used, and their repair and reconditioning are common procedures.

- Several methods are employed for reconditioning aluminium castings.

Possible Methods

- Coated Electrode Arc Welding

- Drying the highly hygroscopic electrode coating at 200°C for at least two hours before use.

- Coating includes alloys (Mg, Cu), excess silicon, and a fluxing agent.

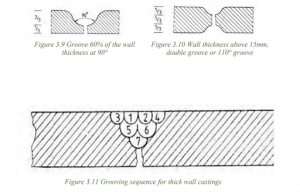

- Cleaning and defect site preparation, which can include grooving or drilling.

- Preheating the area around the fault location (150-200°C).

- Using a 2.5 mm diameter electrode with 50 A current and reverse polarity to break down the oxide layer and access the base metal.

- AWI (Argon Shielded Tungsten) Welding

- Similar preheating requirements as electrode arc welding.

- For up to 15 mm wall thickness, a 4 mm diameter electrode, 220 A welding current, 10 mm arc length, and left-hand welding are used.

- Continuous monitoring of melt penetration, with immediate repairs on the hot workpiece if insufficient.

Conclusion

- Repair welding of iron castings and reconditioning of aluminium castings are essential techniques in maintenance.

- These methods allow for the cost-effective restoration of components, extending their useful life.

- The choice of method depends on factors such as material, part size, and desired results.