Lesson 3: Methods that meet today’s requirements – flame metal spraying

In this lesson, we will explore one of the methods that meets today’s requirements for cost-effective individual and small series production, as well as achieving quality and durability exceeding the original – Flame Metal Spraying.

Introduction

In order to meet the new requirements for repair and renovation, i.e. to achieve cost-effective individual and small series production, and to achieve quality and durability that exceeds the original, the following methods have been widely used:

- Flame spraying of metallic powder

- Flux cored metal spraying welding

- Casting repair welding

- Hard metal surfacing

- Application of plastics

Flame Metal Spraying

- Overview

- Flame metal spraying, or more accurately, cold metal powder spraying, is a method that addresses these needs effectively.

- Basic equipment such as acetylene and oxygen cylinders is readily available, making it accessible even in simple locksmith shops.

- A wide range of alloy powders is commercially available.

- The process involves depositing spherical alloy powder onto the surface to be treated using a mixture of acetylene and oxygen, which becomes plasticized by heat.

- Procedure

- The sequence of operations includes preparation and cleaning of the component, pre-machining of the surface, application of a primer coat, application of filler powder, finishing, and quality control.

- Preparation involves cleaning the surface from physical and chemical contamination and testing its suitability.

- Pre-machining and roughening prepare the part’s shape and surface for bonding.

- Primer powder ensures stable adhesion.

- Filler powder composition is selected based on component material and expected stresses.

- Topcoat application follows specific rules like spray temperature control and machining allowance.

- Advantages

- Cold metal spraying offers flexibility in varying alloying elements.

- The resulting surface is corrosion-resistant and has excellent lubrication properties.

- Surface hardness can be controlled, making it suitable as a replacement for other surface treatments.

- Limitations

- Not suitable for dynamic loads.

- Unsuitable for point or linear contact.

- Should not be used in areas subject to high thermal stress.

- Applied layers can be porous.

- Applications

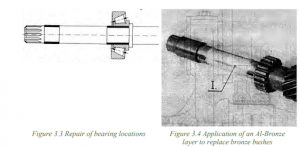

- Flame metal spraying finds applications in shaft bearing locations and bearing bushes.

Conclusion

- Flame metal spraying, or cold metal powder spraying, is a method that meets modern requirements for cost-effective repairs and renovations.

- It offers flexibility in alloy composition, corrosion resistance, and controlled hardness.

- While it has limitations, it is a valuable technique for specific applications.