Lesson 3: WELDING III – welding processes, fusion welding processes

In this lesson, we will delve into fusion welding processes, which employ various heat sources to create strong bonds between materials.

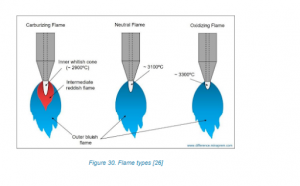

- GAS WELDING

- Gas welding utilizes burning as a heat source.

- Acetylene burned in oxygen produces a high flame temperature of 3160°C.

- Caution is essential due to acetylene’s explosive nature.

- Proper ventilation is crucial to prevent carbon monoxide formation.

- Although less commonly used now, it was valued for its independence from electricity.

- THERMITE WELDING

- This process relies on chemical energy as well.

- It begins with a reaction initiated by a thermite igniter or an acetylene-oxygen flame.

- Temperatures exceeding 2000°C are required.

- The reaction produces thermite iron and significant heat.

- Cooling is necessary, and steel pieces are added for this purpose.

- Alloy quality is achieved through additives like coke, manganese, silicon, titanium, and vanadium.

- ELECTROSLAG WELDING

- Electroslag welding is a mechanized process using Joule heat.

- Initially, it starts as an arc welding on a cutoff plate.

- The heat of the arc melts the welding flux to form slag.

- Slag takes over current conduction, extinguishing the arc.

- SUBMERGED ARC WELDING

- A high-power, automated process suitable for long seams on thick plates.

- An electrical arc burns between the consumable wire electrode and the workpiece.

- Welding flux is fed onto the workpiece, and a vacuum cleaner collects unused flux.

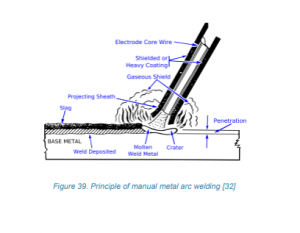

- MANUAL METAL ARC (MMA) WELDING WITH COATED ELECTRODE

- An early arc welding process.

- Arc forms under the protection of the electrode coating.

- Versatile and cost-effective, used for various metals.

- Limited deposition rate and quality affected by human factors.

- GAS METAL ARC WELDING

- Gas Metal Arc Welding (GMAW) processes are highly productive and easily automated.

- It utilizes a burning arc between a mechanically fed consumable wire electrode and the workpiece.

- Protective gas flows through a nozzle to shield the weld and stabilize the arc.

- Inadequate gas protection can lead to issues such as gas porosity and alloying element loss.

- Shielding gas can be inert or active, e.g., Argon and Helium.

- TUNGSTEN INERT GAS (TIG) WELDING

- TIG welding employs a non-fusing tungsten electrode and a shielding gas.

- It is manually guided, similar to gas welding.

- Arc can be ignited by lifting the electrode or using a high-frequency igniter.

- Various electrode materials and diameters are available.

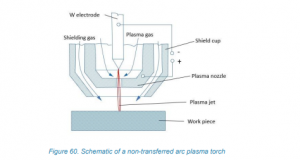

- PLASMA WELDING

- Plasma is a medium with high temperatures and ionization.

- Plasma welding uses an electric arc to create plasma.

- Temperature can reach 5000-50000°C.

- Various gases are used for plasma formation.

- Plasma arc characteristics differ from regular arcs.

- LASER WELDING

- Laser stands for Light Amplification by Stimulated Emission of Radiation.

- Laser-active material is brought into a state of population inversion, resulting in amplified emission.

- Laser welding involves an intense, focused laser beam.

- Precise and efficient, it’s used for various applications.

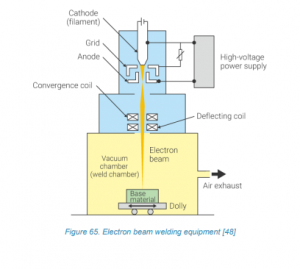

- ELECTRON BEAM WELDING

- High-speed electrons in an electron beam are converted into thermal energy on impact with the workpiece.

- Welding is conducted in a vacuum chamber to avoid rapid electron deceleration due to air particles.

- Precautions include demagnetization, radiation protection, and cleanliness.

Conclusion:

- Fusion welding processes utilize diverse heat sources, from burning gases to laser beams, to create strong material bonds.

- Each welding method has distinct advantages and is chosen based on factors like material type, thickness, and application.

- Safety and precision are paramount in welding, as processes may involve high temperatures, potential hazards, and specific techniques.

- Understanding these fusion welding processes equips professionals with the knowledge to select the right method for various welding applications.

- Welding continues to play a critical role in industries ranging from construction to aerospace, underlining its importance in modern manufacturing.

In this lesson, you’ve explored a variety of fusion welding processes that use different heat sources to create strong bonds between materials. Each process has its advantages and applications, making them valuable tools in various industries.