Lesson 8 Recycling and reusing to reduce waste

Recycling and Reusing to reduce waste

Recycling and reusing materials from vehicles play a huge role in reducing waste.

These efforts have a ripple effect on other related industries. For instance, recycled steel contributes to energy savings in the steel manufacturing industry. To maintain the integrity of the material, the companies have adopted closed-loop recycling. This means adopting self-sufficient recycling processes.

However, only 80% of a vehicle is recyclable. The remaining unrecyclable parts end up disposed of in landfills. Reusing and selling these unrecyclable materials is a more viable option.

Car manufacturing companies are also using parts that are easy to dismantle. This ensures the separating of parts is easy and safe, without damaging the parts.

Example:

Rombat SA is the largest producer of car batteries in Romania [[i]]. Rombat is present both in European countries, such as France, Italy, Germany, Serbia, North Macedonia, Bulgaria, the Republic of Moldova, Greece, Hungary, Russia, Ukraine, Spain, as well as in Asia, Africa and North America [[ii]].

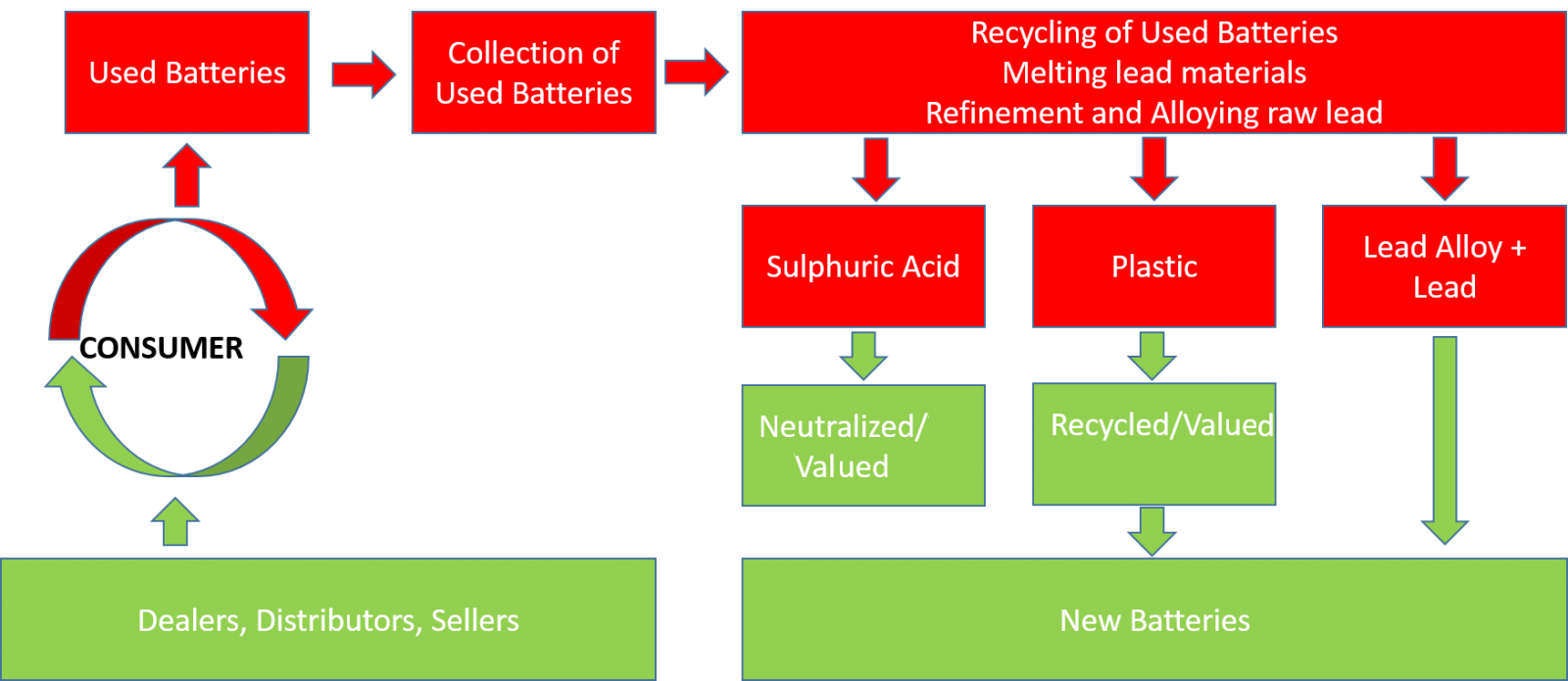

Since 2005, the company has been collecting vehicle batteries to extract the lead they contain, recycle them and manufacture new batteries. The batteries are processed at the 3.7 ha Rebat facility in Copșa Mică [[iii]]. Over 83% of the battery weight is reused in new processes (3‑5. Figure). Rombat encourages owners of used automotive and industrial batteries in ebonite or polypropylene boxes to contact them for collection and cooperation. The company recycles part of the 30 000 tons of batteries that are placed on the market in Romania each year. ROMBAT distributes batteries in more than 3000 stores across the country, as well as in Europe. The company aims to reduce its environmental impact by improving its batteries and enhancing battery recycling services to avoid using up more of Romania’s natural resources.

3‑5 Figure_ROMBAT Recycling Process of the batteries

[Source: https://www.rombat.ro/en/company/rebat/]

ROMBAT applies the operating principles of the circular economy, annually managing to recycle 24,000 tons of used batteries, 98 percent of this amount being reintroduced into the production cycle [[iv]].

The company extracts around 12 000 tons of lead from old batteries each year, making it one of the leading car battery recyclers in Romania. Over 83% of a battery’s weight is reused when it is recycled; lead, lead alloy and plastic are reused in new batteries.

[[i]] https://www.rombat.ro/ro/home/

[[ii]] https://www.transilvaniabusiness.ro/2021/05/24/rombat-sa-trecem-la-nivelul-urmator/

[[iii]] https://www.rombat.ro/en/company/rebat/

[[iv]] https://www.economica.net/ciuca-a-asigurat-rombat-ca-guvernul-sprijina-companiile-care-investesc-in-sustinerea-energiei-verzi-societatea-vrea-sa-si-extinda-productia-de-baterii-litiu-ion_652860.html